Our Products

The corrosivity of FlamePRO® brand fire retardant treated wood has been evaluated in accordance with AWPA Standard E12 for a variety of metals.

The corrosion rates for carbon steel, galvanized steel, aluminum, red brass, and copper are not significantly increased by FlamePRO® brand fire retardant chemicals when the treated wood products are used as recommended by the manufacturer and properly sized for the materials selected.

The following metal fasteners are recommended for use in contact with FlamePRO® brand fire retardant treated wood: 2024-T3 aluminum, SAE 1010 steel, SAE 1012 hot-dip zinc galvanized steel, copper, or red brass.

Hygroscopicity testing conducted by a third party independent laboratory has confirmed that compared to untreated wood, FlamePRO® brand fire retardant treated wood does not pick up excessive moisture under ASTM D3201 test conditions.

Treatment with FlamePRO® does not cause fasteners to corrode. The treating industry recommends the use of hot dip galvanized or stainless steel fasteners for all types of treated wood due to exposure to the weather.

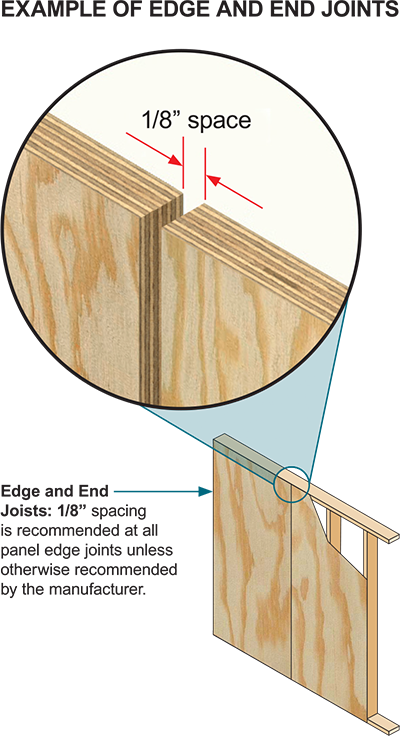

APA recommends a 1/8-inch space between panel edge and end joints. Plywood and oriented strand board (OSB), like all wood products, will expand or shrink slightly with changes in moisture content. If the wood structural panels are tightly butted, there is no room for expansion and buckling can occur. That can mean costly, time-consuming callbacks. To assure best performance, follow these panel spacing and nailing recommendations for APA Rated Sheathing, APA Rated Sturd-I-Floor®, and APA Rated Siding.

Use a 10d box nail to gauge 1/8-inch spacing between panels. Spacer-type panel edge clips may also be used for roof sheathing applications.

Panel spacing is an APA RECOMMENDATION, to provide installers with a means of minimizing the potential for panel buckling; however, it is not a requirement. Some manufacturers may require a space at the time of installation. Panel buckling may be an aesthetic or serviceability issue but is not a structural deficiency. There is no reason to expect this recommended space to be maintained when the panel becomes acclimated. Gaps that were initially present may have closed due to normal moisture-related expansion. If the flatness of sheathing or flooring panels is acceptable, APA would generally recommend that any finish flooring, siding or roofing be installed as planned regardless of whether gaps are present.

FlamePRO® is UL Classified with an FR-S Rating for flame spread and smoke development values of 25 or less and received the UL GREENGUARD Gold Certification. Products certified to these criteria are suitable for use in schools, offices, and other sensitive environments. FlamePro® FRT wood as described in the ICC Evaluation Services, Inc. ESR-4244, meet all major building code requirements

For more information, download the FlamePRO® Fastener and Hardware Information Sheet.